Comprehensive Utilization Technology of Low Temperature Waste Heat Recovery of Blast Furnace Slag Flushing Water and Steam

Category:

Coal combustion emission control & clean energy substitutes

Applicant:

Beijing IVYQUEN Energy Conservation Technology Co., Ltd.

Country:

China

Technology Overview:

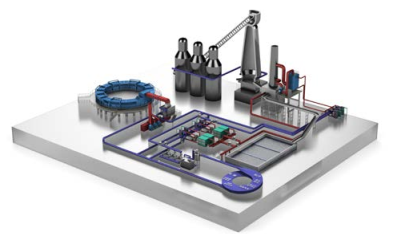

◎◎ The technology recycles heat from slag-washing water of blast furnace and slagwashing vapor, which supplies the heating for the factories and residents nearby and it can also be used for heating, cooling, power generation and seawater desalination in other seasons. ◎◎ Main processes include purification of slag-washing water from blast furnace, and efficient thermal exchange between washing water and softened industrial water. Cooled washing water is then reused in blast furnace, and heated industrial water to support heating and other production processes. ◎◎ Efficient circulation system for waste heat recovery from slag-washing water, integrated with high-precision filtration unit, high-efficiency thermal exchanger, smart operation systems and monitoring and control instruments. ◎◎ Adopts advanced techniques, such as high-efficiency thermal exchange, precise filtration, and self-cleaning, to achieve stable and efficient waste heat recovery from blast furnace slag-washing water. ◎◎ Utilizes titanium materials and nano-coating technology to improve corrosion resistance to face the challenge of complex water quality.

Environmental Features:

◎◎ In combination with the heat demand of northern China, recovering waste heat

from slag-washing water and vapor is beneficial for reducing coal and natural gas

combustion, as well as cutting emissions of relevant pollutants and greenhouse gases.

Financial Features:

◎◎ The investment payback period of the whole system is 1-2 years depending on the distance between heat recovery site and the users.

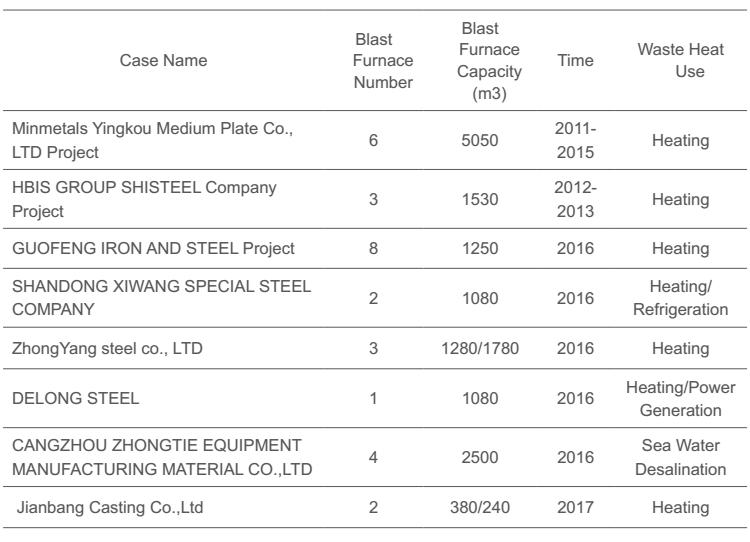

Implementation Status:

Over 40 projects, regarding heat recovery from slag-washing water and vapor, have been

applied in the Beijing-Tianjin-Hebei region in recent years, involving over 70 blast furnaces.